Many types of valves are available for industrial purposes, in which butterfly is one of them. It helps in controlling the media flow. This quarter valve can be turned to 90 degrees through a pipe section/ It is used in waste treatment systems.

You cannot compare it with another valve when it comes to durability. Before you buy it, you must know more about this valve. You must understand how a butterfly valve functions for different applications.

What is the Working Principle of the Butterfly Valve?

A metal disc, a butterfly, is mounted on a rod or stem for rotation. It is easy to shut off the circumference of the resilient seat. The stem mounting can be done in the center or attached offset.

For extra sealing, use the packing component for better protection. There will be no risk of fire due to the rubber seat. If you want to control fluid or gas flow, you need to rotate the valve to some degrees in a single direction.

How to Operate a Butterfly Valve?

There are many ways to operate the disc component of the valve. Such as:

1. Handwheel

You need to turn the handwheel in an opening or closing position. It is the only way through which you can operate this device. It comes with a manual control instead of the automatic one. You can use these valves where you do not need any automatic operation. It can be used with a wheel, gear, or lever. The common applications are power generation plants, refineries, etc.

There are power-operated actuators for controlling the opening and closing of the valve. The major advantage of using a handwheel is an emergency when you do not have the power to operate the system.

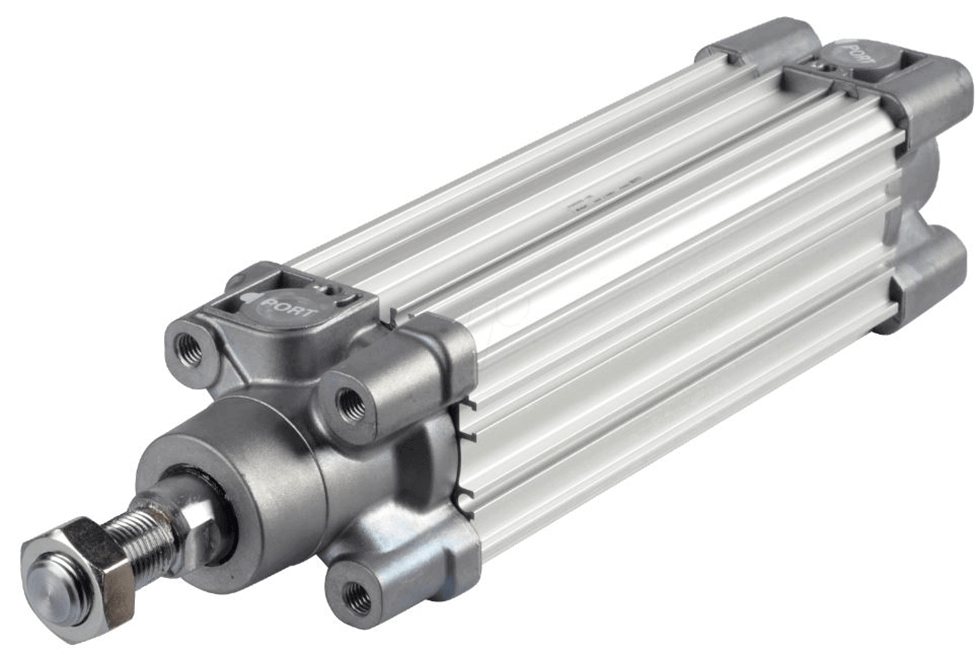

2. Pneumatic Actuators

You can use these automatic or semi-automatic actuators by using gas or air. It is pretty easy to use because of its simple design. There is a certain pressure range in the system. The diaphragm helps in modulating the opening and closing of the valve. It is perfect for throttling.

There is no switch limit used in the system. There are two operations, i.e., Spring return to induce the air pressure that helps spring move. The other one is double-acting, in which the air is passed to two inlets for opening and closing movements.

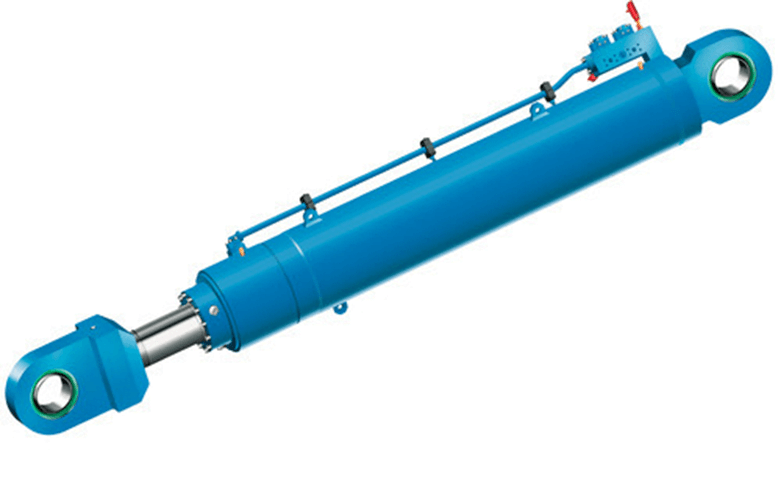

3. Hydraulic Actuators

These actuators are automatic, and they can sense the pressure of the fluid. When it senses the fluid, it controls the valve movement. Any application which requires massive force requires hydraulic actuators. The fluid pressure is used as a piston-cylinder for converting the linear motion.

After that, the piston connected to the actuator turns the linear into rotary motion. It gives the torque to the butterfly valve part and opens up when the pressure is high as per the set value. It closes down automatically when the downstream pipe bled.

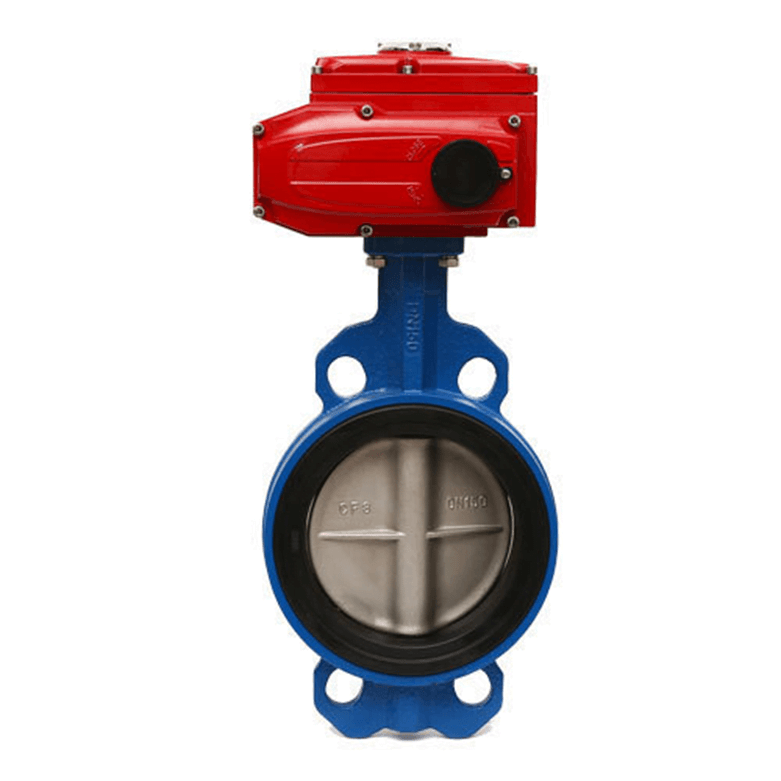

4. Electric Butterfly Valves

An electric actuator is attached to the stem to control the valve’s opening and closing. You need electricity to operate such a valve. If you need this device for big plants or industries, it can be the best option.

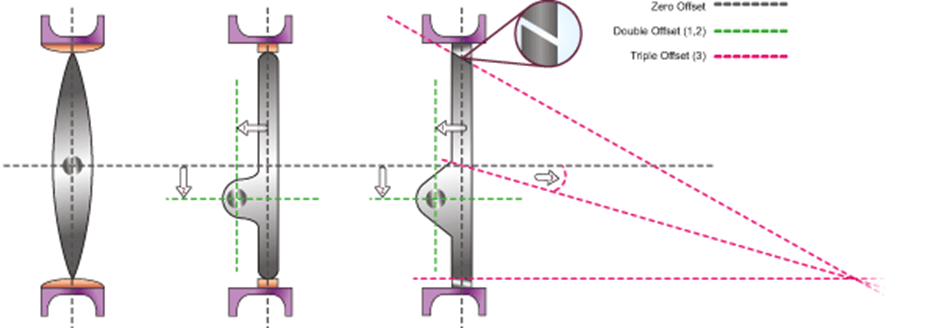

How Butterfly Valves of Different Offset Function?

1. Zero Offset

It is also known as a concentric valve. The stem line is placed at the center of the valve body. The position of the disc is concentric. It is perfect for applications with low temperature and pressure. A zeolite manufacturer can prefer such butterfly valves with zero offset.

You can choose any actuator like electric, pneumatic diaphragm, handwheel, or hydraulic. The disc moves in either the perpendicular or parallel direction to handle the fluid flow. If you consider it for throttling, then it may work slowly.

2. Double Offset

It is perfect for high pressure and temperature applications because of the metal valves. It is comparatively durable, and hence, it can bear intense conditions. The double offset can be used in constructing a DIY floating dock. Due to the dual offset design, there is less scope of friction in between the metal surfaces. The design is quite simple to operate. It is affordable and perfect for handling heavy-duty flow control.

3. Triple Offset

Compared to the zero or double offset, assembling and manufacturing this type of butterfly valve is quite challenging. It is quite expensive but available with many benefits. It is perfect for tight shutting off the pipes like gas or petroleum applications. All the triple offsets are mounted eccentrically for a better and tighter seal. There is no sliding of the disc and seat on the stem to control high temperature and pressure.

Conclusion

A butterfly valve can be operated in many ways with different offsets. The main job of this device is to control the flow of the fluid at different temperatures and pressure. Understand how it functions to determine the suitable applications for different butterfly valves. This device is commonly used in many industries. Choose the right one that you need for your job.