Using low-cost silicone moulds and a Vacuum Casting Services, Therefore, high-quality prototypes and small batches of parts can be produced quickly and affordably. Surface detail and fidelity to the original pattern can be seen in copies made in this manner.

Vacuum casting service plays vital role in our life. Because, a lot of examples present regarding Silicone Injection Molding. Due to Vacuum casting service our daily life work become so easy to do.

CNC Machining Services:

serp provides a variety of precision CNC machining services including milling, turning, EDM (electrical discharge machining) and wire EDM, and surface grinding. So your team can focus on getting your product to market, we can handle all technical aspects of creating your prototypes and parts with our precision 3-, 4-, and 5-axis CNC machining equipment. If you need a precision machining firm for plastic and metal CNC machining parts, 3ERP is the ideal place to go. Contact us today to receive your production solution and specifics.

Vacuum Casting – Urethane Casting:

SERP is completely capable of addressing and your vacuum casting and silicone moulding demands.

We can make your plastic parts to the highest grade, as well as cost-effectively and quickly. Due to our years of experience in the business. Vacuum casting service is an excellent approach to produce stiff or flexible parts. Due to it is ideal for high quality prototypes, function testing, concept proofing and display demos.

Mold Making Services:

Need mould forming supplies for mass production parts? SERP is China’s largest mould maker. With mould production capabilities in house and resources from our partners. We are able to produce plastic injection moulds for both rigid plastics and rubbers, metal injection moulds for every type of precision stainless steel parts, and pressure. Die casting moulds for aluminium, magnesium and zinc. We offer low-cost local manufacturing moulds and high-quality exporting moulds for all your project needs.

Rapid Tooling Services:

Also known as rapid tooling or bridge tooling. A time- and cost-effective method of producing prototypes. Its means to carry out low-volume injection moulding for a number of types of plastic parts. It can be used to mould numerous copies of a part. So fast tooling is used to make mouldings for rapid prototype needs. Bridge the gap before high-volume manufacturing.

Injection Molding:

Need to swiftly test out the market with low-volume parts? Or wish to generate vast amounts of production parts? Then you can’t go wrong with our injection moulding services. At SERP, we make high-quality prototype mouldings from aluminium moulds with rapid turnaround times. Our customers may try out their concepts for manufacturability and functioning, rapidly.

Our 3D Printing Services:

With Binashree’s exclusive line-up of 3D Systems‘ greatest, you’ll never again have to limit your ideas in the world of 3D printing. If you can dream it, we can help you make it a reality. Allow you to swiftly and cost-effectively actualize your ideas as physical items with our 3D Systems printers.

3D Printing Process:

Choosing the right 3D printing technology and making the most of its advantages begins with determining your specific needs across the full design-to-manufacture process.

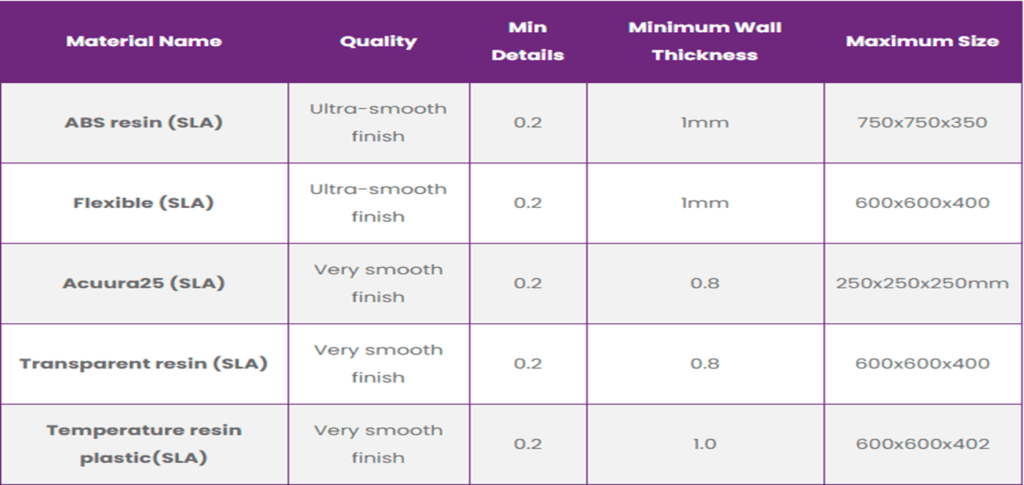

SLA 3D Printing

Stereolithography uses photochemical methods. An additive manufacturing process, to create items layer by layer. Cross-linking of chemical monomers and oligomers forms polymers. With the aid of CAD software, an ultraviolet laser is focused on a vat of photopolymer resin. A single layer of the desired part is created by photochemically solidifying the resin.

The build platform then lowers another layer of resin and coatings the tank once again. After the resin has been removed from the surface, the part is rinsed with the solvent. This 3D printing technology is quite commonly utilised.

Major Benefits :

- Reduced price

- Less time in the press

- Quite a bit of room inside

- Accessible to the general public

- It has a slick finish.

Uses:

- Prototyping for new products, the medical industry, So, a slew of other uses are all made possible by this versatile material’s inexpensive cost.

- Images from CT and MRI scans are used.

- The Medical Sector SLA can be used to produce 3D models of the patient’s body in various parts. Because, Data can then be utilised to help plan, develop, and manufacture implants.

- Developing a prototype

- This technology produces low-cost, high-precision prototypes.It has numerous applications.

3D Printing Performance Attributes You Need To Know:

3D printers all have varied file-to-finished part speeds that include build preparation, print speed, post-processing requirements, and optional finishing.

Part Cost:

It’s critical to understand. Price will be considered fully. To begin, you must understand the vendor’s part cost estimates. After that, Use our Buyer’s Guide to help you deal with vendors during the purchasing process.

Advantages Of Vacuum Casting:

- Molds are inexpensive.

- A few days is all it takes to construct a mould.

- Overmolding polyurethane resins are just one of the many options for casting.